Basic Information

Product Description

Product Features

Application Field

Basic Information

| Model | YY-WS1 |

| MOQ | 1 roll |

| Payment | 300PCS per item |

| Place of Origin | Fujian, China |

| Certification | ISO9001,ISO14001,SGS,ROHS,MS,BSCI |

| Delivery Time | 4-15 days |

| Sercice | OEM, ODM, Customized |

| Start Port | fuqing, Fujian |

| Certification | ISO9001,ISO14001,SGS,ROHS,MS,BSCI |

Product Description

The Waste Discharge Tape, also known as silent waste tape, polarizer film tearing tape, stripping tape, or adhesive tape, is a specialized tape used in the assembly and installation processes of LCD screens, touch screens, and optical polarizers. It is designed to facilitate the transmission of polarizers and the stripping of off-type protective films.

Product Features

- This tape is constructed using specially treated polyester film (PET) that provides durability and strength. The film is coated with a special pressure-sensitive adhesive that offers secure bonding and easy removal when necessary.

- The Waste Discharge Tape plays a crucial role in the attachment of LCD and touch screen OCA (Optically Clear Adhesive) optical polarizers. It is used for precise and efficient stripping of various protective films, allowing for accurate placement and alignment during the assembly process.

- The tape is designed to be gentle on delicate surfaces, ensuring that it does not cause any damage or leave adhesive residue behind. It provides reliable adhesion to the protective film, allowing for clean and seamless removal without leaving any marks or residue on the components.

- Special sizes and colors of the Waste Discharge Tape can be produced based on customer requirements, ensuring flexibility and customization to meet specific application needs.

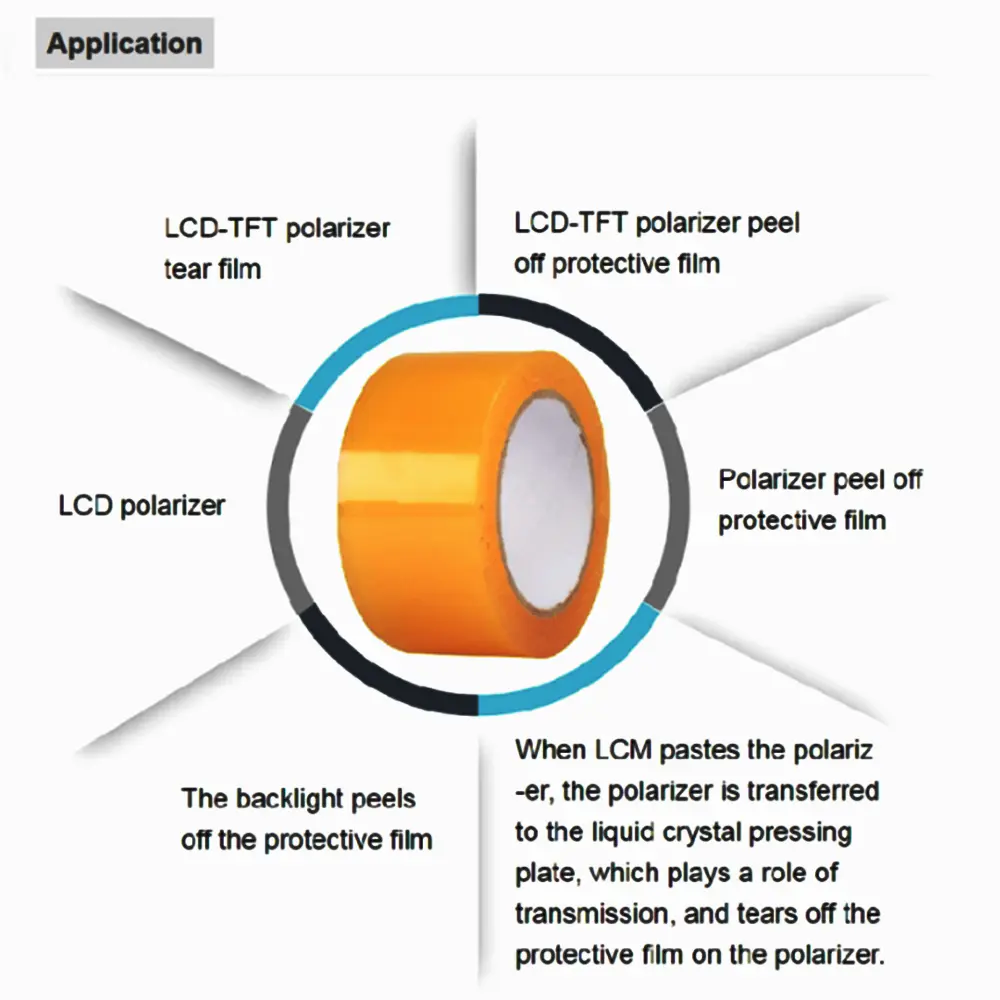

Application Field

The Waste Discharge Tape is a specialized adhesive tape that assists in the smooth and precise installation of LCD screens, touch screens, and optical polarizers. Its specially treated PET film and pressure-sensitive adhesive make it a reliable choice for efficient stripping and removal of protective films, contributing to the successful assembly of electronic devices.